Flotation Cell Ball Mill Wear Resistant Plate

Flotation solutions TankCell® Metso

2022年9月8日 a tailormade flotation circuit for your plant that will deliver optimized cell volume, froth carry rate, and residence time Wide range of cell sizes TankCell flotation units are built Combining the benefits of circular cells with the unique features of the DV (Deep Vane) mechanism, the RCS™ (Reactor Cell System) flotation technology has been developed to create ideal conditions to maximize flotation performance RCSTM flotation cell Metso Corporation PDF 2021年3月24日 Wear resistance at the nanoscale is one of deterministic factors in influencing the efficiency and reliability of MEMS/NEMS assemblies The application of thin lubricant layers with high elastic moduli and hardness on Recent Progress on Wear‐Resistant Materials: 2022年5月11日 TankCell flotation units are built to last, with components and electrical equipment selected for maximum operating life For instance, Metso Outotec rotors and Flotation technologies Metso Outotec keeping costs

Technological assessments on recent developments in fine

2022年4月1日 Several flotation cells including Jameson, Reflux™ and Imhoflot™ cells, oscillating grid flotation cell and staged flotation reactor were presented as efficient cells for 2021年11月1日 In comparison with the traditional graphite processing flowsheet that uses cone crusher, ball mill or rod mill, and mechanical flotation cell, the new process offers a number of An innovative flake graphite upgrading process based on 2024年3月1日 This study explored 440 C steel ball wear resistance via mechanical ball milling with Al 2 O 3 powder We used a customized grinding jar to compare heattreated, untreated, Improving the wear resistance of 440 C bearing steel balls 2014年3月21日 METALLURGICAL TESTING [Sparks, NV USA] Flotation Dry Wear Components Multotec’s high quality, hardwearing flotation components are available all types Flotation MULTOTEC Wear Components Resources

Friction and wear characteristics and simulation study of

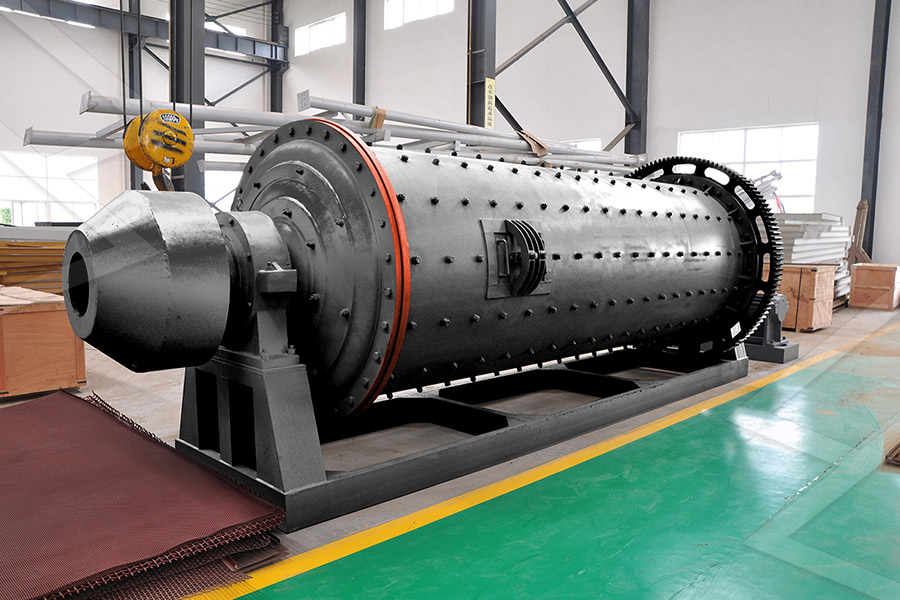

2024年9月12日 This enables us to explore the friction behavior and wear mechanism between the liner and grinding balls, providing an essential theoretical basis for enhancing the wear 2023年5月18日 Product Introduction Ball mill is the key equipment for crushing raw materials again after being broken It is widely used in cement silicate, new construction matcrials, refractary materials, fertilizes, black and nonferrous Ball Mill MECRU Heavy Industry Technology2024年10月14日 The rotary gear is processed by casting hobbing The cylinder is embedded with a wearresistant lining plate, which has good wear resistance The batch mill runs smoothly and works reliably 【Batch Ball Mill Working Batch Small Ball Mill JXSC MachineAvailable for all flotation cell types and sizes, Multotec’s range of wet end flotation wear components include hoods, dispersers, stators and rotors, which can be customised according to your froth application Hoods Manufactured with radial veins, Multotec hoods include shaft protection, rotors, mounting nuts and protector capsWet End Flotation Wear Components Multotec

Five Reasons and Solutions for the Rapid Wear of Ball Mill Liner

2022年5月9日 As an important part of the ball mill, the lining plate can not only effectively protect the barrel of the ball mill and effectively increase the load, but also enhance the impact and grinding between the medium and the material, thereby improving the grinding efficiency However, in the production process, the longterm action makes the Continue reading Five 2016年4月14日 A 100 lb representative sample of the ball mill feed is sufficient for the unit cell flotation tests Flotation in a Grinding Circuit The simplest flotation circuit is a comparatively recent innovation It consists of the introduction of a flotation cell into the grinding circuit between ball mill and classifier as shown belowFlash Flotation with Closed Circuit Grinding 911Metallurgist2014年3月21日 BALL MILLS [New York, USA RSA,] Tema Systems Inc VIBRATORY SCREEN PANELS [Cincinatti, OH USA] and sizes of flotation cells They are replaceable components and can be redesigned Optimal wear resistance Optimal impact resistance Modular stators available RotorsFlotation MULTOTEC Wear Components Resources 2019年11月30日 flotation machines application Flotation machine can be used for separating copper, leadzinc ore, molybdenum ore, graphite ore, fluorite ore, phosphate, selected gold, silver, iron, rare earth ore, talc and so on It is widely used in the separation and recovery for fine minerals of ferrous metal, precious metal, nonferrous metal, nonmetallic minerals, rare metal, flotation machine ballmillsales

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 Comminution is a very important and resultdetermining step in mineral processing This is because further downstream processes in the beneficiation chain depend entirely on it2022年5月11日 TankCell flotation units are built to last, with components and electrical equipment selected for maximum operating life For instance, Metso Outotec rotors and stators have proven to be the most wearresistant available The wide range of cell sizes enables a compact, economical, and efficient plant design without theFlotation technologies Metso Outotec keeping costs 2023年6月29日 Flotation machines consist of several key components, including: Tank: The tank is the vessel where the flotation process takes place It is typically made of steel and is designed to withstand the pressure and wear and tear of the flotation process The tank is often divided into several compartments to allow for multiple stages of prehensive Guide to Flotation Machines: Principles, A high efficiency and energy saving ball mill with rolling bearing Capacity Up to 160t/h Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grindingXinhai Products Center Xinhai

Flotation Cells Design Operating Characteristics

2017年5月21日 The Air Flow Number should lie within a narrow range for optimum flotation results for any one cell Harris gives values for most commercial cells while Table 4 has more detailed data for Denver and Wemco cells based on more recent measurements for sizes up to over 30m (1,000 cu ft)2024年7月10日 Froth flotation has become one of the main methods for separating mineral raw materials in the world, and flotation machine is an important equipment in the flotation process, which can be categorized into two types, ie, mechanical flotation equipment, flotation columns, and reactor/separator type flotation equipment However, due to longterm exposure to What are the reasons for flotation machine impeller wear? What wear 2016年5月30日 Flash Flotation Cell The “SubA” Flash Flotation Cell, when installed in the circuit between the ball mill and classifier, makes possible the quick recovery of coarse free mineral, which is a vital factor in economic mill operationSlime losses from overgrinding are reduced to a minimum with the use of the “SubA” Unit Flash Flotation Cell, resulting in Flash Flotation Cell and Flotation Banks 911Metallurgist2016年1月5日 The grates and wear plates are normally made from alloy wear resistant cast steel or rubber They are ribbed to prevent racing and excessive wear The dischargers and pans are generally made from either wear resistant cast iron or rubber, or wear resistant fabricated steelSlot plugging can be a problem in grate discharge mills Whether the Ball Mill Liner Design 911Metallurgist

.jpg)

WEMCO Selfaspirated flotation cells wear parts FLSmidth

Don’t lose time to flotation cell downtime Rely on WEMCO wear parts – designed and built by the industry leaders in flotation technology Gyratory Crusher Wear Plates Jaw Crusher EB and EB Pro Jaw Crusher Liners PERI™ AutoCharge Mill Grinding Ball Charging System PERI™ Online Slurry Analysis System Transfer Point Alignment 2022年9月1日 Flotation Machine; Wet Ball Mill; Shaking Table; Spiral Chute; Cement Machines Cement Grinding Unit; Cement Mill The flotation cell's impeller with high strength alloy material is wearresisting and which consists of pulley, impeller, vertical shaft, etc The impeller is made of wearresistant rubber Inflating device: It is made up of Flotation Machine FTM Mining Machine2024年10月3日 CITICHL has the ability to offer solutions for all kinds of mills, such as cement mill, mine mill, ball mill, rod mill, AG mill, SAG mill, and etc Features: l Material: High Manganese Steel, SuperHigh Manganese Steel, High Chromium Casting Iron, Alloy Steel, Chromiummolybdenum Steel, Low Carbon Steel, or as per the customer requestsWear Resistant Rubber Liner Plate for Ball Mill Liner Plate 2024年8月30日 The requirements for the ball mill liner plate include wear resistance, and materials such as hardened steel, high manganese steel, chrome steel, alloy cast iron, rubber, and magnetic liner plates can be chosen The functions of the ball mill liner plate are manifested in the following three aspects:Ball Mill Liner Plate: Function, Manufacturing and Maintenance

.jpg)

Graphite Ore Beneficiation Process: An Overview Mining

2023年4月15日 Graphite, a naturally occurring form of crystalline carbon, is a valuable mineral resource due to its unique properties such as high electrical and thermal conductivity, resistance to chemical reactions, and excellent lubricating capabilitiesAs a result, graphite finds a wide range of applications in industries such as batteries, lubricants, and advanced composite 3 天之前 1Established in 1997,2 5 years experience in wear solutions products 2Factory is under expanding, the total construction area is 50,000 sqm 3ISO9001:20 15 certified,over 350 staffs 4Three Owndesigned production lines, the ball mils are own produced6 Inch X 4 Inch Ceramic Alumina Tiles for Sliding Abrasion2024年9月12日 Friction and wear test equipment, scanning electron microscope, abrasion balls made of CGr15 high carbon chromium bearing steel, and liners made of NM500 steel were used for wear simulation and friction–wear experiments The variation trends of friction coefficient, wear amount, and subsurface characteristics under dry friction and slurry conditions were studied Friction and wear characteristics and simulation study of Essa® laboratory ball and rod mills are well known for efficient grinding – they are low cost, hardwearing and trusted WEMCO II Flotation Cell; WEMCO Wear Parts; Hydromet Hydromet Counter Current Decantation The barrels and balls are optimised for longterm wearresistance and low contamination levels ensuring the integrity of the Essa laboratory ball and rod mills FLSmidth

Advanced mill liner wear measurement and prediction

Boost mill productivity and improve processing performance by understanding your mill liner wear with mill liner profiling and 3D scanning from FLSmidth WEMCO II Flotation Cell; WEMCO Wear Parts; Hydromet Hydromet Counter Current Decantation Counter Current Decantation Gyratory Crusher Wear Plates Jaw Crusher EB and EB Pro The selfaspirating WEMCO flotation technology, whether incorporated into the original 1+1 flotation machine design or the newergeneration SmartCell ® flotation cell, combines ease of operation with improved metallurgical performance The result is excellent particle recovery in a simple, proven inducedair designInducedair flotation cell FLSmidthWith 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, JXSC has been providing premium services, from RD and production to installation and free operation training Applying steel balls as grinding media, Ball Mills Manufacturer JXSCIt is a unit of several combinations of several cells, varying from two to ten cells Left or right type flotation machine can be supplied as required by customer 2 Technical Specifications of Mechanical Agitating Continuous Flotation Cell 3 FX flotation machine is mainly consist of : ①Cell It is made of welded steel plateContinuous Flotation Cell ZJH minerals

Flotation Wear Components Multotec

Highquality, hardwearing and available with short delivery times, wherever your plant is, we manufacture replaceable flotation wear components for all flotation cell types and sizes Our wet and dry end wear components include rotors, impellers, diffusers, hoods, dispersers, stators, guards, base plates, bearing stands, draft tubes and standpipesWhy choose Metso RCS™ flotation cell? Enhanced performance • Maximum bubbleparticle contact within the mechanism and the flotation tank • Effective solids suspension and resuspension • Effective air dispersion and distribution throughout the cell volume • Smooth froth surface and removal Reduced operating costs and more sustainability • Extended wear life RCSTM flotation cell Metso Corporation PDF Catalogs2023年10月24日 After Being Treated By Advanced Flat Vulcanizer, It Has The Characteristics Of High Elasticity And Strong Hardness, Which Makes The Lining Plate Of The Ball Mill Have Good Wear Resistance Compared With High Manganese Steel Lining Plate, The WearResistant Rubber Lining Plate And Polyurethane Ball Mill Lining Plate Show Excellent Cost PerformanceBall Mill Liner ( Rubber , Polyurethane ) Mill Rubber Linings Plate 2023年5月18日 Product Introduction Ball mill is the key equipment for crushing raw materials again after being broken It is widely used in cement silicate, new construction matcrials, refractary materials, fertilizes, black and nonferrous Ball Mill MECRU Heavy Industry Technology

Batch Small Ball Mill JXSC Machine

2024年10月14日 The rotary gear is processed by casting hobbing The cylinder is embedded with a wearresistant lining plate, which has good wear resistance The batch mill runs smoothly and works reliably 【Batch Ball Mill Working Available for all flotation cell types and sizes, Multotec’s range of wet end flotation wear components include hoods, dispersers, stators and rotors, which can be customised according to your froth application Hoods Manufactured with radial veins, Multotec hoods include shaft protection, rotors, mounting nuts and protector capsWet End Flotation Wear Components Multotec2022年5月9日 As an important part of the ball mill, the lining plate can not only effectively protect the barrel of the ball mill and effectively increase the load, but also enhance the impact and grinding between the medium and the material, thereby improving the grinding efficiency However, in the production process, the longterm action makes the Continue reading Five Five Reasons and Solutions for the Rapid Wear of Ball Mill Liner2016年4月14日 A 100 lb representative sample of the ball mill feed is sufficient for the unit cell flotation tests Flotation in a Grinding Circuit The simplest flotation circuit is a comparatively recent innovation It consists of the introduction of a flotation cell into the grinding circuit between ball mill and classifier as shown belowFlash Flotation with Closed Circuit Grinding 911Metallurgist

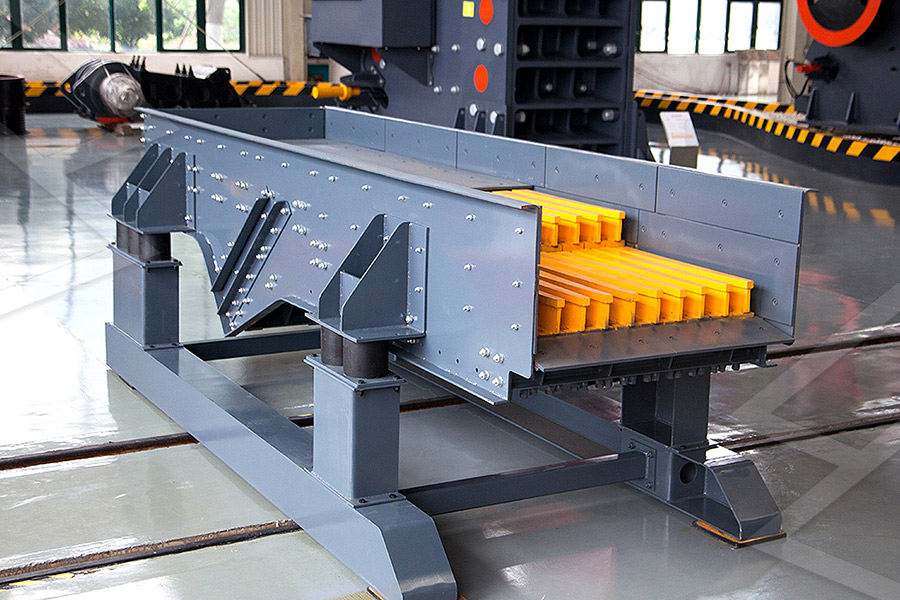

Flotation MULTOTEC Wear Components Resources

2014年3月21日 BALL MILLS [New York, USA RSA,] Tema Systems Inc VIBRATORY SCREEN PANELS [Cincinatti, OH USA] and sizes of flotation cells They are replaceable components and can be redesigned Optimal wear resistance Optimal impact resistance Modular stators available Rotors2019年11月30日 flotation machines application Flotation machine can be used for separating copper, leadzinc ore, molybdenum ore, graphite ore, fluorite ore, phosphate, selected gold, silver, iron, rare earth ore, talc and so on It is widely used in the separation and recovery for fine minerals of ferrous metal, precious metal, nonferrous metal, nonmetallic minerals, rare metal, flotation machine ballmillsales2023年4月23日 Comminution is a very important and resultdetermining step in mineral processing This is because further downstream processes in the beneficiation chain depend entirely on it(PDF) Grinding Media in Ball MillsA Review ResearchGate2022年5月11日 TankCell flotation units are built to last, with components and electrical equipment selected for maximum operating life For instance, Metso Outotec rotors and stators have proven to be the most wearresistant available The wide range of cell sizes enables a compact, economical, and efficient plant design without theFlotation technologies Metso Outotec keeping costs

Comprehensive Guide to Flotation Machines: Principles,

2023年6月29日 Flotation machines consist of several key components, including: Tank: The tank is the vessel where the flotation process takes place It is typically made of steel and is designed to withstand the pressure and wear and tear of the flotation process The tank is often divided into several compartments to allow for multiple stages of flotation