Crusher Mantle Shaft

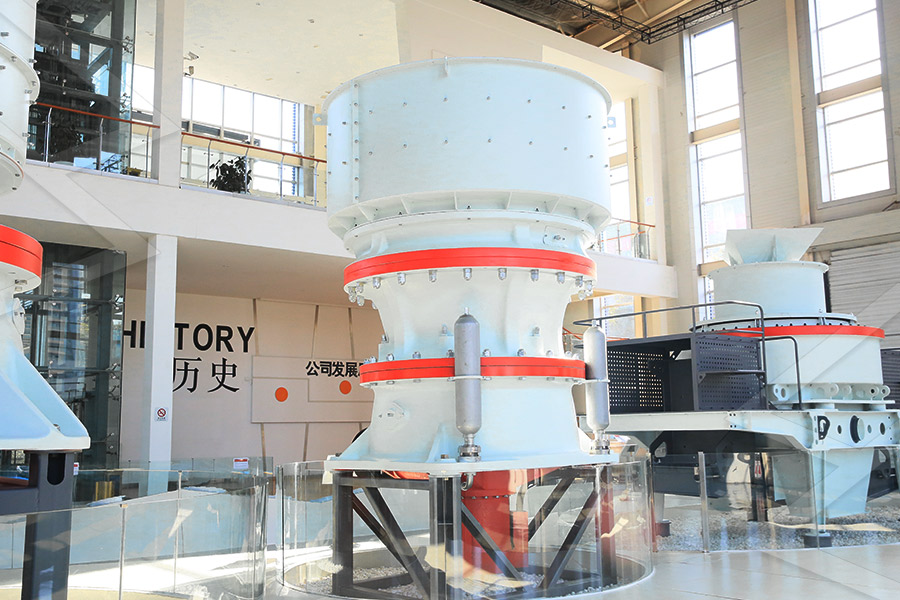

Rocky案例|圆锥破碎机析模界

2024年3月29日 创建cone crusher的运动,这些运动由以下运动定义: Mantle围绕垂直轴做偏心旋转,压迫Concave上的颗粒并促进破碎。同时,它可以自由地围绕Shaft旋转。 Mantle Axis和Rotation Axis的交点表征了Pivot Point。 右键单 2020年10月1日 On this basis, the impacts of the mantle shaft angle, the concave angle, the eccentric angle, and the mantle shaft speed on the gyratory crusher performance are explored Simulation and optimization of gyratory crusher The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)Cone Crushers (Parts of a Cone Crusher) 2016年1月1日 The nutational motion is actualised by an eccentric bushing transferring the rotational motion of the drive shaft via a gear ring to the main shaft, see Fig 1 The mantle is Cone crusher modelling and simulation using DEM

.jpg)

Cone crusher basics in 4 minutes SRP

The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing product As the smallest distance between the concave and the mantle, the 2021年5月1日 To optimize the crushing chamber of the gyratory crusher, the discrete element method (DEM) is used to explore the influence of the concave curve height, concave curve Simulation and optimization of crushing chamber of gyratory crusher 2022年2月11日 Chen et al discussed the influence of the concave curve radius, eccentric angle, and mantle shaft speed of the gyratory crusher on the crushing chamber performance based on the DEM analysis modelAn Improved Capacity Model of the Cone 2023年2月22日 The eccentric assembly consists of a main shaft, a mantle, and a set of bushings that allow the mantle to rotate around the main shaft The eccentric motion of the mantle creates a crushing action that compresses the Understanding Cone Crusher Parts: Names,

.jpg)

Chamber Optimization for Comprehensive Improvement of Cone Crusher

2021年3月15日 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the 2022年11月3日 shaft travel length allows excellent manganese wear part utilization (scrap rate), which results in less frequent liner changes and less waste That is also why its possible for Greatest application fit Nordberg® GP Series™ cone 2023年11月1日 The part where this failure occurred is the eccentric bushing As the mantle shaft comes into direct contact with the eccentric bushing, a large ring of deposited layer can be observed in the middleupper part of the lower shaft, as shown in Fig 2 (a) This phenomenon indicates that strong oxidation has occurred at that locationFailure analysis of eccentric bushings in large gyratory crusher2017年2月19日 Cone Crusher MANTLE The Mantalloy head mantle of this cone crusher is a replaceable wearing surface It is made of alloyed manganese steel, and is held in place with a selftightening head nut FORGED Cone Crusher Parts 911Metallurgist

Gyratory Crusher (Gyratory Crushers Explained)

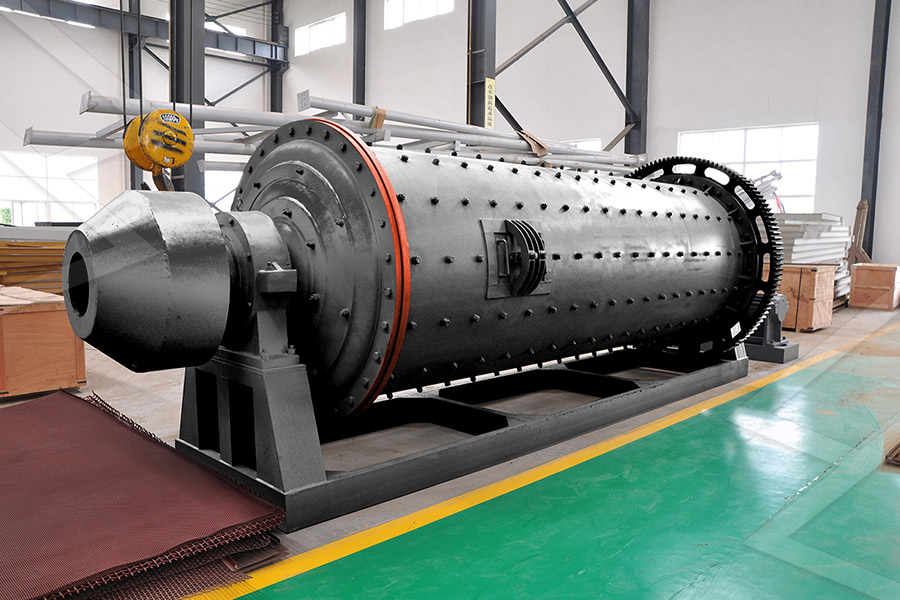

The mantle and concaves from the working surfaces of the crusher, producing the force required to crush the ore Eccentric motion is achieved by the lower eccentric bushing and drive arrangement on the bottom of the main shaft 2020年10月1日 The surface of the mantle shaft and the shell is fixed with many liners, and they are eccentrically installed The space enclosed by the outer surface of the mantle shaft and the inner surface of the shell is the crushing chamber When the gyratory crusher starts to work, the pinion shaft assembly drives the eccentric rotation of the mantle shaftSimulation and optimization of gyratory crusher 2021年12月28日 top of the shaft attached to the crushing cone is supported centrally in the bushings, and the bottom of the shaft is positioned in an The crushing chamber, also known as the crusher cavity, is composed of a mantle and concave segments 99 Examples of single tier (left) and double tier (center) chambers Chamber segment thickness (right Application guide SUPERIOR® primary gyratory crusher 2023年6月14日 Mantle: The mantle is a wearresistant liner that covers the cone crusher’s main shaft and forms the crushing surface against the concave It protects the main shaft from wear and provides a crushing chamber for the material Concave/Bowl Liner: The concave, also known as the bowl liner, is a wearresistant liner fixed to the bottom of the cone crusher’s crushing Cone Crusher Wear Parts Replacement JXSC Mineral

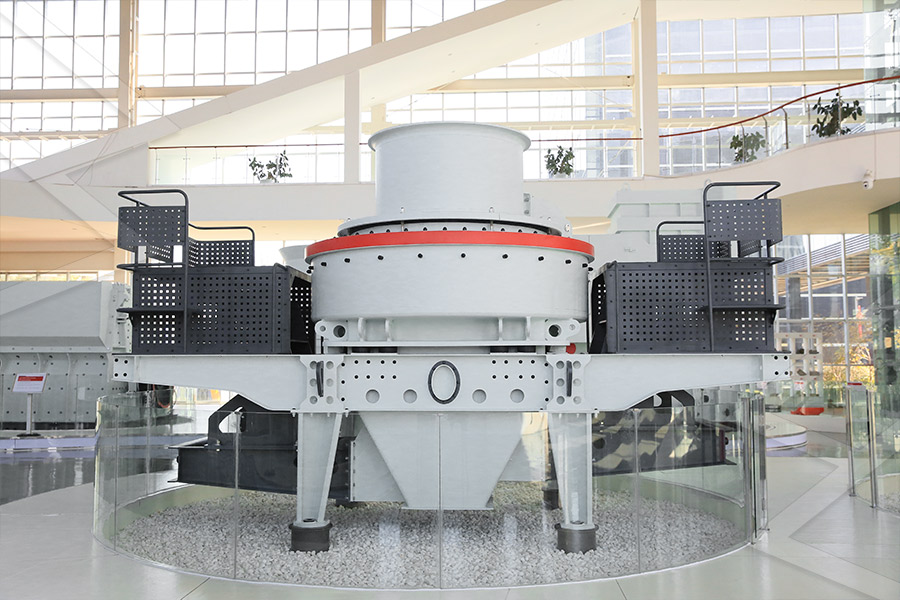

Gyratory Crusher Cone Crusher Mantle Differences

2015年7月25日 The other most noticeable change is the crushing action of the mantle In the Gyratory all the movement is in the bottom of the crusher mantle This is due to the angle that the main shaft is on The greater angle of the cone crusher puts the pivot point below the distributor plate While the pivot point for the gyratory crusher is at the 2023年2月22日 Crushing chamber and mantle: The crushing chamber is the space between the concave and the mantle, where the material is crushed The mantle is a fixed part of the cone crusher that is connected to the eccentric assembly As the mantle rotates, it moves closer to and further away from the concave, creating a crushing action that reduces the Understanding Cone Crusher Parts: Names, Functions, and 2016年2月17日 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing soft and medium Gyratory Crushers 911Metallurgist2023年8月2日 The walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone The ore is discharged through the smaller bottom output hole of the cone While the cone does not move, an interior crushing movement is created by a revolving shaft on a vertical rodTypes of Crushers: What You Need to Know HUATAO GROUP

.jpg)

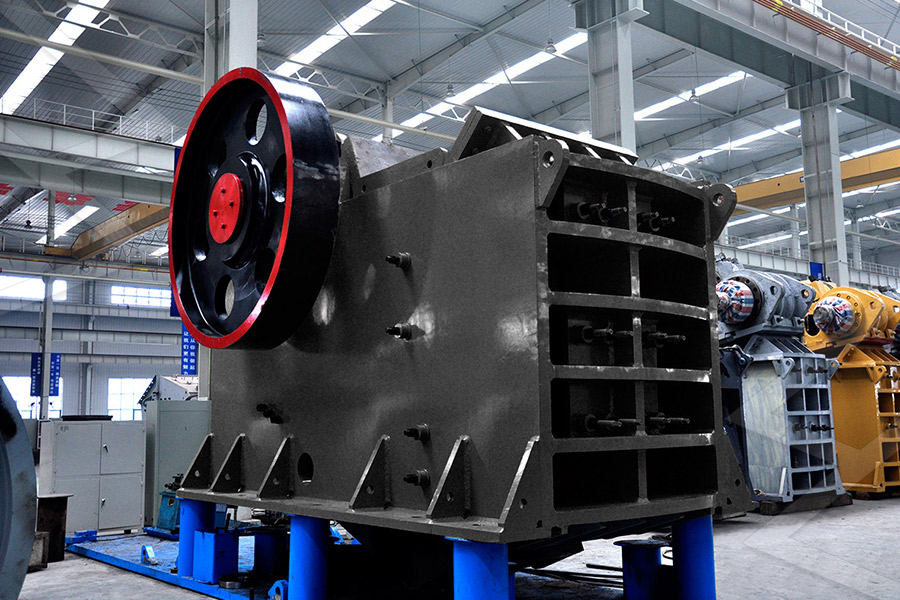

Types of Crushers Explained: Everything You

2024年4月19日 Gyratory Crusher: Uses a rotating mantle within a concave surface to compress and crush material: Largescale primary crushing applications, high capacity The rotor is the core element of an impact The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing product As the smallest distance between the concave and the mantle, the Cone crusher basics in 4 minutes SRP2024年3月29日 创建cone crusher的运动,这些运动由以下运动定义: Mantle围绕垂直轴做偏心旋转,压迫Concave上的颗粒并促进破碎。同时,它可以自由地围绕Shaft旋转。 Mantle Axis和Rotation Axis的交点表征了Pivot Point。 右键单 Rocky案例|圆锥破碎机析模界1 天前 Check out our Symons cone crusher parts range Skip to content Main Menu HOME; PRODUCTS Menu Toggle JAW CRUSHER PARTS Menu Toggle Jaw Plate; Pitman; Eccentric Shaft; Toggle Plate; CONE CRUSHER PARTS Menu Mantle: Symons 3' 68633701: COUNTER SHAFT: Symons 3' 45451786: HOUSING SPRING: Symons 3' 36807701: Nordberg Symons Cone Crusher Parts GTEK MINING GTEK CRUSHER

.jpg)

Gyratory Main Shaft Mantle Removal Marion

2024年9月26日 18006271639 Specializing in rock crusher repair since 1934 Capabilities Capabilities Overview; Machining; Welding; Portable Machining Services Gyratory Main Shaft Mantle Removal Nov 24 of 2020 SHARE THS POST ON; The Previous Post ; Our Metso HP 800 Mainframe had a loose shaft and we refit the shaft back to OEM specs with a 2week 2024年4月1日 The gyratory crusher is mainly composed of the mantle, mantle shaft, concave, shell, and eccentric sleeve, as shown in Fig 1 There are plenty of liners installed on the surface of the mantle shaft and shell, the inner surface of the liner installed on the shell is concaveDEM simulation and optimization of crushing chamber 2023年8月29日 Delve into the technical nuances and benefits of cone crusher mantle and concave components Explore how these critical parts influence crushing efficiency and product quality Discover our topselling mantle and concave products, meticulously designed to enhance cone crusher operation Elevate your crusher's performance with our backing compound Optimal Crushing Performance with Cone Crusher Mantle 2021年12月28日 top of the shaft attached to the crushing cone is supported centrally in the bushings, and the bottom of the shaft is positioned in an The crushing chamber, also known as the crusher cavity, is composed of a mantle and concave segments 99 Examples of single tier (left) and double tier (center) chambers Chamber segment thickness (right Application guide SUPERIOR® primary gyratory crusher

Metso HP500 cone crusher bronze mantle bowl liner tiger

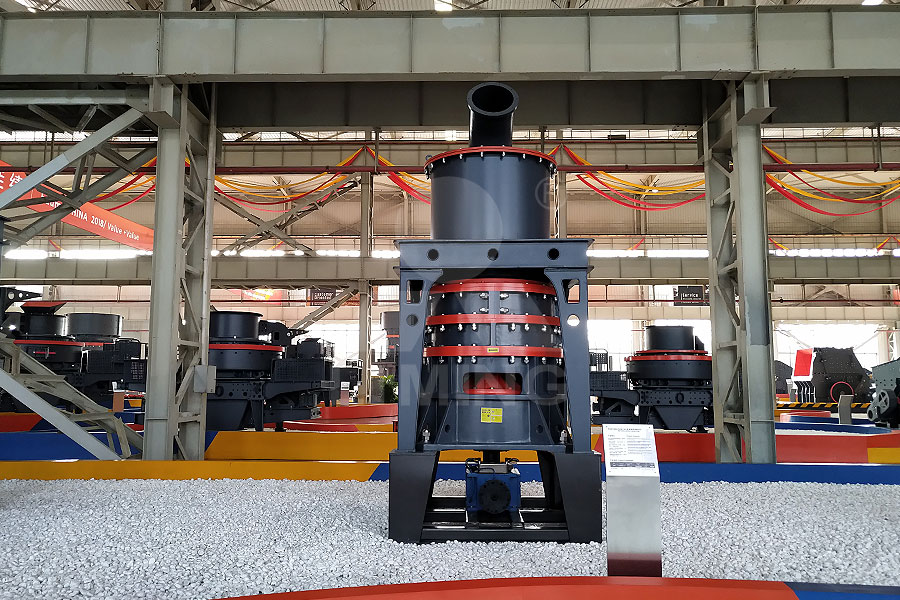

Metso HP500 cone crusher bronze mantle bowl liner tigermachinery Languages English German French Spanish Arabic Russian Portuguese Polish TAPER BUSHING REMOVER MOTOR SHAFT: : ROD 0156 , AMPCOTRODE 10: MM: PC AND PRINTER HIGH VOLTAGE ELETRIC: : PRESSURE SW P/N 9012GAW4Y1, Energy in the VSI Crusher, proceedings of European Symposium on Comminution and Classification 2015, Gothenburg, September 2015 Paper B Simon Grunditz, Magnus Evertsson, Erik Hulthén, Magnus Bengtsson, The Effect of Rotor Tip Speed of a Vertical Shaft Impactor on the Collision Energy Spectrum, proceedings of Minerals EngineeringModeling of Vertical Shaft Impact Crushers Chalmers2016年1月1日 Image of the 3D scanned crusher mantle When performing a 3D scan the resulting output is a point cloud It is not possible to use a point cloud directly in a DEM simulation as representation of geometry The model is based on the mechanics and the actual geometrical dimensions of eg the angles of the mantle, shaft lengths and Cone crusher modelling and simulation using DEM2023年8月7日 Precrushed material fed in via the top of the cone crusher flows over the mantle while the vertical cone crusher drive shaft rotates the mantle The mantle performs eccentric movements under the concave (also called bowl MCC Series Cone Crusher Minyu Machinery Corp

Gyratory Crusher an overview ScienceDirect Topics

The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the 2024年1月1日 As to gyratory crushers, Pothina et al (2007) developed a mathematical model to help predict energy consumption and analyze the primary factors influencing energy consumption Chen et al (2020) conducted multiobjective optimization studies on cone crushers, considering factors such as the mantle angle, concave angle, eccentric angle, and mantle shaft rotation Study on productivity of eccentric roll crusher based on how mantle works cone crusher, bowl and mantle for cone crusher bowl and how concave and mantle shape being applied 5 how crusher is fed ie shaft impact crusher LockLift Mantle Lifting System Boosts Safety, Productivity Mantle Shaft For Crusher Crusher Mills, Cone Crusher, Jaw 2021年5月1日 The gyratory crusher consists of a mantle shaft, a shell, a pinion shaft assembly, and a position system [26], the mantle shaft and the shell are eccentrically installed The outer surface of the mantle shaft and the inner surface (concave) of the shell form a crushing chamber The concave is composed of a curved segment and a straight segmentSimulation and optimization of crushing chamber of gyratory crusher

Cone Crushers Shaft Impactor Crusher Manufacturer from

Manufacturer of Cone Crushers Shaft Impactor Crusher, Cone Crusher, Cone Mantle offered by APC Engineering Works, Nashik, MaharashtraSymons 2 feet ~ symons 7 feet cone crusher mantle, bowl liner Sandvik CH420 ~ CH880, CS420 ~ CS660 cone crusher mantle, concave pinion shaft for HP100 ~ HP800, GP100 ~ GP550 cone crusher Eccentric shaft for C63 ~ C3054 jaw crusehr [Product features] Strong bearing capacity, high strength, low price, long working life View details Send Cone crusher and cone crusher wear spare partsSandvik CH840i cone crusher rockmachinery Main shaft assembly excluding mantle: 4528361901: Top shell assembly excluding concave: BG: Pinion shaft housing assembly excluding pulley: Close ZHEJIANG ROCK MACHINERY CO, LTD Registered in China Registration number: MACQ9CX477Sandvik CH840i cone crusher parts database and search Shinsh is a specialized supplier of crusher wear parts and supply solutions for the mineral processing, aggregates, construction and recycling industries We are good at providing various crusher spare parts and wear parts, such as jaw crusher, cone crusher, gyratory crusher, horizontal shaft impactor, vertical shaft impactor, etc to help Crusher Wear Parts Manufacturer, Jaw Plate, Mantle

Failure analysis of eccentric bushings in large gyratory crusher

2023年11月1日 The part where this failure occurred is the eccentric bushing As the mantle shaft comes into direct contact with the eccentric bushing, a large ring of deposited layer can be observed in the middleupper part of the lower shaft, as shown in Fig 2 (a) This phenomenon indicates that strong oxidation has occurred at that location2017年2月19日 Cone Crusher MANTLE The Mantalloy head mantle of this cone crusher is a replaceable wearing surface It is made of alloyed manganese steel, and is held in place with a selftightening head nut FORGED Cone Crusher Parts 911MetallurgistThe mantle and concaves from the working surfaces of the crusher, producing the force required to crush the ore Eccentric motion is achieved by the lower eccentric bushing and drive arrangement on the bottom of the main shaft Gyratory Crusher (Gyratory Crushers Explained)2020年10月1日 The surface of the mantle shaft and the shell is fixed with many liners, and they are eccentrically installed The space enclosed by the outer surface of the mantle shaft and the inner surface of the shell is the crushing chamber When the gyratory crusher starts to work, the pinion shaft assembly drives the eccentric rotation of the mantle shaftSimulation and optimization of gyratory crusher

Application guide SUPERIOR® primary gyratory crusher

2021年12月28日 top of the shaft attached to the crushing cone is supported centrally in the bushings, and the bottom of the shaft is positioned in an The crushing chamber, also known as the crusher cavity, is composed of a mantle and concave segments 99 Examples of single tier (left) and double tier (center) chambers Chamber segment thickness (right 2023年6月14日 Mantle: The mantle is a wearresistant liner that covers the cone crusher’s main shaft and forms the crushing surface against the concave It protects the main shaft from wear and provides a crushing chamber for the material Concave/Bowl Liner: The concave, also known as the bowl liner, is a wearresistant liner fixed to the bottom of the cone crusher’s crushing Cone Crusher Wear Parts Replacement JXSC Mineral2015年7月25日 The other most noticeable change is the crushing action of the mantle In the Gyratory all the movement is in the bottom of the crusher mantle This is due to the angle that the main shaft is on The greater angle of the cone crusher puts the pivot point below the distributor plate While the pivot point for the gyratory crusher is at the Gyratory Crusher Cone Crusher Mantle Differences2023年2月22日 Crushing chamber and mantle: The crushing chamber is the space between the concave and the mantle, where the material is crushed The mantle is a fixed part of the cone crusher that is connected to the eccentric assembly As the mantle rotates, it moves closer to and further away from the concave, creating a crushing action that reduces the Understanding Cone Crusher Parts: Names, Functions, and

.jpg)

Gyratory Crushers 911Metallurgist

2016年2月17日 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing soft and medium 2023年8月2日 The walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone The ore is discharged through the smaller bottom output hole of the cone While the cone does not move, an interior crushing movement is created by a revolving shaft on a vertical rodTypes of Crushers: What You Need to Know HUATAO GROUP