Ball Mill For Working Princal India

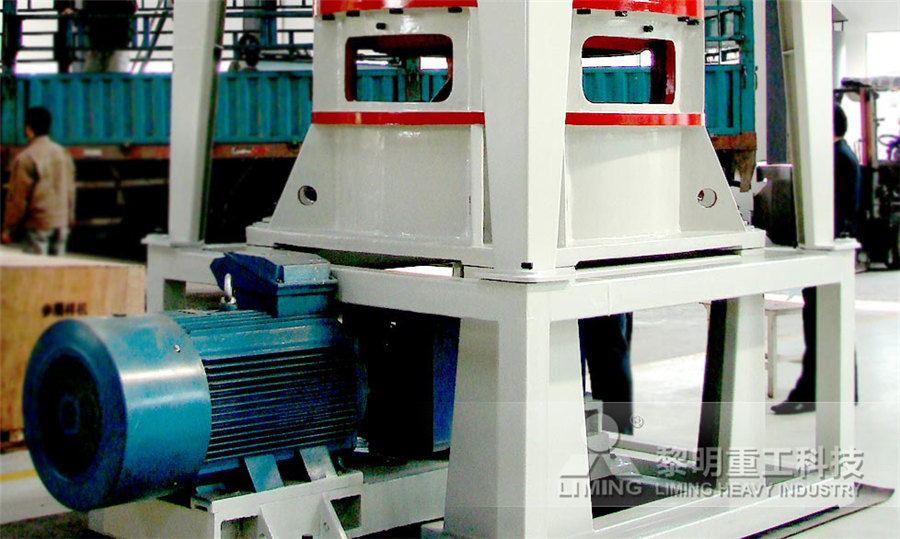

Ball Mill Promas Engineering Pvt Ltd

4 天之前 We deliver the quality based ball mill, which is key equipment for regrinding Promas Engineers is a wellknown name in ball mills manufacturers in India We are manufacturer, supplier and exporter of ball mills according to ISI India’s Leading Manufacturer Exporter of Ball Mill, Continuous Ball Mill, Batch Type Ball Mill About Continuous Ball Mill Heavy duty, continuous type ball mill is with multi compartments Ball Mill Shalimar EngineeringLABINDIA's High Energy Ball Mill MM1600 is a multifunctional benchtop ball mill specially designed for fast preparation of ultrafine sample with high sample throughput capable of handling 6384 samples simultaneously in modern HIGH ENERGY BALL MILLFeatures Designed for optimum particle size reduction for dry solids, our SmartGrind Ball Mill reduces particle size upto 20 micron Available in wide range of capacities from small scale to SMARTGRIND BALL MILLS Renders India Pvt Ltd

.jpg)

Ball Mills Laboratory Grinding Mill Latest Price,

Find here Ball Mills, Laboratory Grinding Mill manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across IndiaIndia’s No 1 Leading Manufacturer Exporter of Ball Mill, Rotary Kiln, Continuous Ball Mill SHALIMAR has a well equipped drawing and design department which finalizes the drawings with high standards of efficiency, performance and Shalimar EngineeringYatherm Scientific is known for its superb quality madeinIndia laboratory Ball mill Our ball mill housing is completely made up of mild steel powder coated The rotating jar cover is designed completely from thick Stainless steel 304 gradeLab Ball Mills 2kg to 100Kg Manufacturer Chanderpur Group has been the first choice of leading companies in the industry for the past few decades for heavyduty, high performance, and durable machines for the manufacturing Biggest Manufacturer and Supplier Of Ball Mills In India

India's Best Quality Ball Mills Manufacturer

4 天之前 We are Manufacturing Batch type Ball mill with capacity from 25 kg to 60 Ton for Ceramic industries, Mining industries, Chemical industries and Pharmaceutical companies as per clients requirements Bhagawati is a well 2018年10月31日 Techno Designs is a ball mill manufacturer with an experience in designing, engineering, and manufacturing over 150 grinding mills We deliver qualityapproved batch type ball mills with sizes in the range of 15m x 2m and Ball Mill Manufacturer, Ball Mill Manufacturer 2024年10月12日 In the mining industry, ball mill are used as grinding equipment at the comminution stage to liberate minerals from barren ores by reducing the feed material size The most common types of grinding equipment are ball The Best Ball Mill Manufacturer, Ball Mill in IndiaHSN Code Product Description; 7325: Other cast articles of iron or steel: : Other: : Grinding balls and similar articles for millsHSN Code for Ball Mill in India Export Genius

Biggest Manufacturer and Supplier Of Ball Mills In India

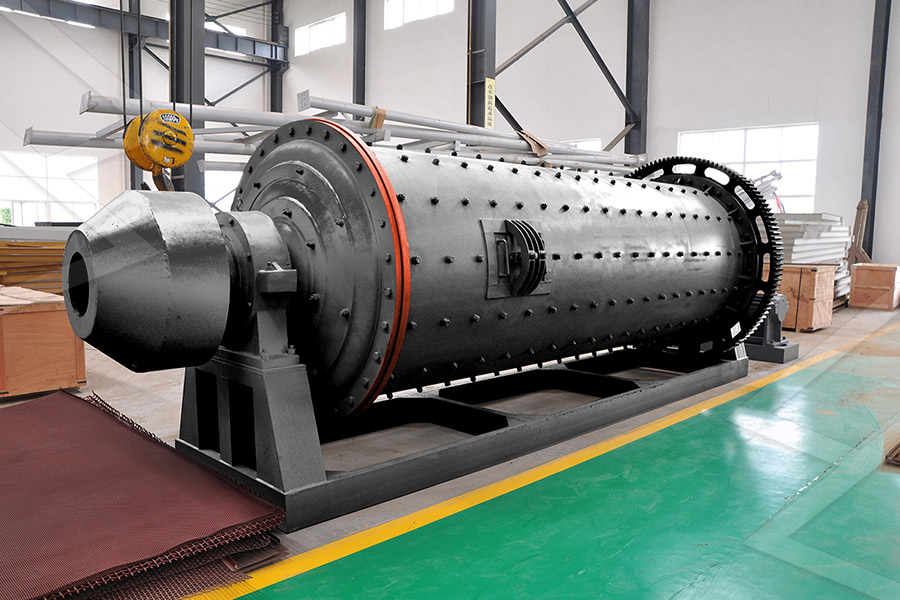

However, the financial year of 20202021 was exceptional We are so proud to announce that CPG has broken all records in ball mills sales Even in the year of the global pandemic, we have supplied more than 30 ball mills making us the biggest manufacturer and supplier of ball mills in India These numbers are exceptional in the industry2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and The working principle of a ball mill is based on the impact and attrition between the balls and the grinding media As the mill rotates, the grinding media (usually steel or ceramic balls) are lifted to a certain height and then allowed to fall freely, causing the materials to be reduced in size by the impact and abrasive forces generated Ball Mill Grinding Machines: Working Principle, Types, Parts HSN Code Product Description; 8482: Ball or roller bearings: : Ball bearings: : Other: 8466: Parts and accessories suitable for use solely or principally with the machines of headings 8456 to 8465 including work or tool holders, self opening dieheads, dividingheads and other special attachments for the machines; tool holders for any type of tool, for working in the HSN Code for Ball Mill Machine in India Export Genius

Ball Mills Suitable for every application Retsch

Basically, the working principle of each ball mill is the same: it is based on the concept that the sample material is moved potentially together with grinding balls inside a closed jar This movement results in strong mixing and crushing effects of the material Ball mills are furthermore characterized by significant differences in the 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process ControlVerticalstand low speed industrial chocolate ball milling system, specially built for medium large chocolate making industry Connected with chocolate conche refiner machine enables the rapid ball mill process within 35hours Chocolate Ball Mill Machine Chocolate Ball Mill Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed Ball Mill (Ball Mills Explained) saVRee saVRee

A Comprehensive Guide to Finding the Best Ball Mill for Sale

A: Ball mills are used for grinding and mixing materials in a variety of industries, from mining and construction to pharmaceuticals and ceramics Q: What are the different types of ball mills? A: There are several types of ball mills, including vibratory ball mills, planetary ball mills, and tumbling ball mills Q: How do ball mills work?2024年9月22日 Exploring the working principle of ball mills A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes It is a cylindrical device filled with balls, which rotate on a horizontal axis to pulverize the material The working principle of a ball mill is based on the impact and friction between the Exploring the working principle of ball mills NEWSThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch The EasyFit range of jars has been specially designed for extreme working conditions such as longterm trials, even at Planetary Ball Mill PM 100 RETSCH highest fineness2023年8月9日 As professional Chinese ball mill manufacturers in India, ZENITH summarizes some key factors of ball mill in the production process During the working process of the ball mill, the reasonable grading of the steel balls is related to the efficiency of the equipment Only by ensuring a certain proportion of various steel balls can it adapt Ball Mill Manufacturers Suppliers in India Zenith Crusher

SMARTGRIND BALL MILLS Renders India Pvt Ltd

Explosion Proof option of Ball Mills renders safe working environment and safe processing RENDERS INDIA PVT LTD CORPORATE OFFICE / FACTORY ADDRESS: SR NO 232/2, ATLAS METAL COMPOUND PUNE NASHIK HIGHWAY BHOSARI PUNE MAHARASHTRA TELEPHONE / FAX : 020 2021年3月12日 in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball mill comminution process has a high electricalBALL MILLS Ball mill optimisation Holzinger ConsultingThe Ball Mill Liners can be fashioned from composite or rubber The material chosen depends on the customer’s specific needs Cast metal alloy was traditionally used to make inserts These are added to the framework of the liners at specific points where Super Quality Ball Mill Liners Manufacturers in IndiaFind here Ball Mills, Laboratory Grinding Mill manufacturers OEM manufacturers in India Get Contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across IndiaBall Mills Manufacturers Suppliers in India India Business

17 Signs of Problems with Ball Mills: Quickly

2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to 2023年11月8日 Working of Ball mill The working of a pharmaceutical ball mill involves several steps and processes aimed at reducing the particle size of pharmaceutical materials, mixing or blending ingredients, and achieving Ball mill Principle, Construction, Working2016年11月8日 Design engineers generally use Bond Work Index and Bond energy equation to estimate specific energy requirements for ball milling operations Morrell has proposed different equations for the Work Index and specific energy, which are claimed to have a wider range of application In this paper an attempt has been made to provide a comparison of these two Estimation of the Specific Energy Requirement for Size Reduction 2015年11月30日 If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases During grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various ages Ball mill produces 1 to 50 ton/hr of powder and energy requirement Ball Mill PPT SlideShare

Mechanical Operation Lab and Disc Pulverizer Manufacturer

Mechmin Mechanical Operation Lab, Disc Pulverizer Rod Mill Manufacturer from Thane, Maharashtra, India Mechmin Mechanical Operation Lab, Disc Pulverizer Rod Mill Manufacturer from Thane, Maharashtra, India MECHMIN engineered Ball Mill consists of a cylindrical shell with Curved end flanges Welded to the shell Bonds Work Index 2022年3月30日 Overview of Ball Mill Ball mill, also known as tumbling or pebble mill is milling equipment that encompasses cylindercontaining balls and is mounted on a metallic frame that can be rotated along with a longitudinal axis Introduction to HighEnergy Ball Mill: Working Principle, Advantages, and Features Posted by Alex Brown on Mar 30, 2022 Introduction to HighEnergy Ball Mill: Working Principle, 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum GrindingBall Mill Manufacturers in India India is a leading manufacturer of ball mills, with several companies operating in the country The ball mill manufacturing industry in India has been growing at a steady pace, thanks to the increasing demand from various sectors such as cement, mining, and pharmaceuticals, among othersBall Mill Principle, Application, Uses, Critical Speed, Diagram

Selected Advances in Modelling of Size Reduction in Ball

2023年9月22日 chemical industries are subjected to grinding in ball mills [1–3] The specic energy consumption for these materials typically ranges from 5 to 50 kWh/ton Thus, the ball mills consume an enormous amount of energy The energy eciency of the ball mill being as low as 1% or less [2], there is considerable incentive to improve the energy eciencyChanderpur Works Private Limited Manufacturer of Ball Mill, Lime Plants Coal Gasifier from Yamuna Nagar, Haryana, India India Chanderpur Works Private Limited Jorian, Yamuna Nagar, Haryana GST No 06AADCC6080A1Z5 home About Us contact us Call 94% Response Rate Send Enquiry our range Ball Mill; Lime Plants; Coal Gasifier;Manufacturer of Ball Mill Lime Plants by Chanderpur 2024年10月12日 In the mining industry, ball mill are used as grinding equipment at the comminution stage to liberate minerals from barren ores by reducing the feed material size The most common types of grinding equipment are ball The Best Ball Mill Manufacturer, Ball Mill in IndiaHSN Code Product Description; 7325: Other cast articles of iron or steel: : Other: : Grinding balls and similar articles for millsHSN Code for Ball Mill in India Export Genius

.jpg)

Biggest Manufacturer and Supplier Of Ball Mills In India

However, the financial year of 20202021 was exceptional We are so proud to announce that CPG has broken all records in ball mills sales Even in the year of the global pandemic, we have supplied more than 30 ball mills making us the biggest manufacturer and supplier of ball mills in India These numbers are exceptional in the industry2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and The working principle of a ball mill is based on the impact and attrition between the balls and the grinding media As the mill rotates, the grinding media (usually steel or ceramic balls) are lifted to a certain height and then allowed to fall freely, causing the materials to be reduced in size by the impact and abrasive forces generated Ball Mill Grinding Machines: Working Principle, Types, Parts HSN Code Product Description; 8482: Ball or roller bearings: : Ball bearings: : Other: 8466: Parts and accessories suitable for use solely or principally with the machines of headings 8456 to 8465 including work or tool holders, self opening dieheads, dividingheads and other special attachments for the machines; tool holders for any type of tool, for working in the HSN Code for Ball Mill Machine in India Export Genius

Ball Mills Suitable for every application Retsch

Basically, the working principle of each ball mill is the same: it is based on the concept that the sample material is moved potentially together with grinding balls inside a closed jar This movement results in strong mixing and crushing effects of the material Ball mills are furthermore characterized by significant differences in the 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control